Improving Fuel Efficiency with Point Cloud Engineering

Aerodynamic Trailer Systems uses the PolyWorks® software solution to help digitize a challenging shape and perform CFD analysis and wind tunnel tests on its inflated truck boattails.

Aerodynamic Trailer Systems Ltd. (ATS), Auburn, Ohio has developed a new product that fits on commercial trailer doors to provide a more aerodynamic shape to the rear of the trailer. The object is a “Green Technology” to reduce emissions by improving fuel efficiency of over-the-road trucks. The product, a boattail, is an aerodynamic device that reduces drag caused by air flowing in a random, turbulent manner around the rear of a commercial trailer. It effectively changes the flat surface of the rear doors to a curvilinear shape.

The Challenge

The design of the boattail, developed by Aerodynamic Trailer Systems, is an inflatable boattail constructed from a heavy-duty flexible polymer material that automatically inflates and deflates by means of a blower and valving system at pre-set highway speeds. The deflated position overcomes a design challenge, by allowing the rear doors to be fully opened for loading freight.

“The inflated boattail is a uniquely curved shape that is very difficult to pre-determine on engineering drawings or measure, which makes it difficult to model,” said Jim Domo, Aerodynamic Trailer Systems Chief Executive Officer. “We wanted to measure the aerodynamic profile of the device. Since a truck trailer is too big to fit in a wind tunnel facility, we needed to create a scaled model that would describe the exact physical shape. In parallel, we needed a digital version of the boattail, in order to perform a software-based computerized fluid dynamic (CFD) analysis.”

The Solution

Aerodynamic Trailer Systems contacted 3D Scan IT, Inc. to discuss alternatives to traditional data gathering techniques. 3D Scan IT is a metrology company and North American Integrator of PolyWorks. They’re headquartered in Royal Oak, Michigan. 3D Scan IT technicians recommended a non-contact high-density scanner as a data gathering approach and brought a Imetric IScan White Light scanner to the company’s facility.

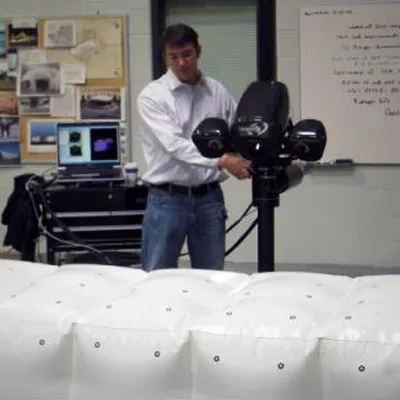

“We first used photogrammetry to set up navigation points on the surface of the boattail, and then we performed a complete scan using the Imetric white light scanning system. Setup and photogrammetry took about two hours including calibration of the scanner, targeting the part, and performing the photogrammetry. The scanning process took about three hours,” stated Bob Squier, President of 3D Scan IT.

Point Cloud Data Management Delivers Quick Results

The data was acquired using the PolyWorks software suite from InnovMetric. A total of 62 scans were taken and registered to the photogrammetry coordinate system. A tolerance-controlled best-fit alignment of the scans was performed in the PolyWorks|IMAlign™ module. The aligned scans were then processed using the PolyWorks|MMerge™ module to create a polygonal mesh that removed all the overlapping scan data while removing the fabric texture and reducing the file size.

The polygonal model was then brought into the PolyWorks|IMEdit™ module to remove photogrammetry targets. A watertight polygonal model was created using the IMEdit functionality of curvature-based hole-filling.

Scanning the boattail

Wind Tunnel Testing

ATS wanted to test the boattail performance in a wind tunnel. “The goal was to create a file that we could use in a rapid prototyping process to quickly create a 1/8 scale model of the boattail device that would be used for performance testing in a wind tunnel,” said Patrick Ryan, President of ATS.

Prototype created from PolyWorks STL model.

To perform the simulation, the polygonal model was sent to Auto Research Center in Indianapolis, Indiana. This wind tunnel testing facility, designed primarily for testing race cars, is an open jet, rolling road design that accurately replicates highway conditions. To create a scaled model of the boattail, the specialist at Auto Research Center used a Stratasys FDM 8000 rapid prototyping machine, and the watertight polygonal model created by 3D Scan IT, Inc. to build the part in ultra-thin layers from strong ABS plastic.

“We planned to use that wind tunnel test data to make any last-minute design changes to the device before we went into production, so it was critical to our program that the model be as accurate as possible,” Mr. Ryan said.

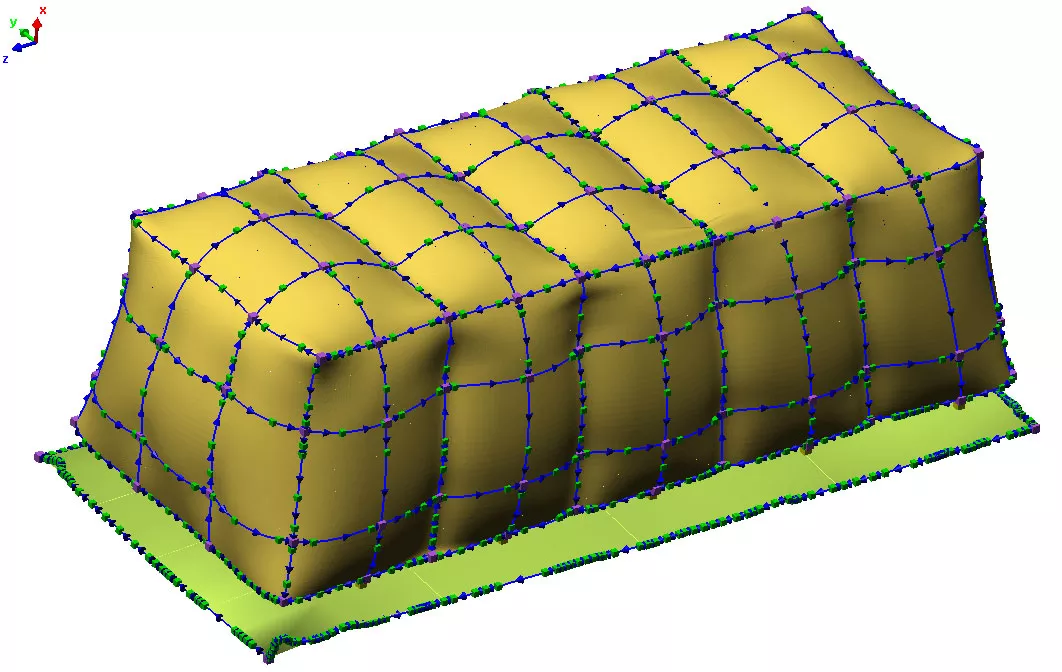

NURBS creation process.

CFD Analysis

In addition to the wind tunnel testing, ATS wanted to perform a CFD analysis. In order to perform this analysis, 3D Scan IT prepared a surfaced model (NURBS model) using the PolyWorks|IMEdit module.

First, a curve network was created by using the curve extraction and editing functionalities of IMEdit. Automatic NURBS surface fitting procedures create the surfaces as the curves are completed. The PolyWorks|IMInspect™ module was used to align the model to the global coordinate system of the trailer doors since the boattail had to exactly fit the door area without obstructing the hinges.

The optimized NURBS model was sent to specialists from NASA to perform CFD analysis. This software provided a quick overview of the aerodynamic performance of the inflatable boattail under various conditions.

The NURBS model was also exported to ATS’s SolidWorks® software suite for use in future modifications and for production purposes.

The Benefits

According to Mr. Domo and Mr. Ryan, the 1/8 scale model of the boattail created by the laser scanning and point cloud data management process was a dimensionally precise model of the full-size device, virtually an exact replica. “We were confident that when we conducted wind tunnel testing we would get meaningful results that would apply directly to the full-size device,” Mr. Ryan said.

Fuel consumption was reduced by up to 5%

Test results indicated that the boattail could reduce fuel consumption by up to 5%. “That translates into fewer emissions and reduced fuel costs through the improvements in aerodynamic drag on the trailer, which decreases the effective load that the tractor must pull thus improving efficiency,” said Mr. Domo. “Plus, we believe that with some minor shape modifications to the device, we can improve our profile even more.” He added that the use of scanning technology and point cloud data management reduced the time to create the model by orders of magnitude. “We were able to get to a precise model in just days,” he said.

Bob Squier of 3D Scan IT, Inc., said that this application was unique in that the entire design and manufacturing process relied on scanning and the refinement of point cloud data, plus rapid prototyping. “A traditional approach to product design and development would simply not have achieved the results the company was looking for."