What’s New in PolyWorks|Inspector™ 2023

3D Dimensional Analysis & Quality Control

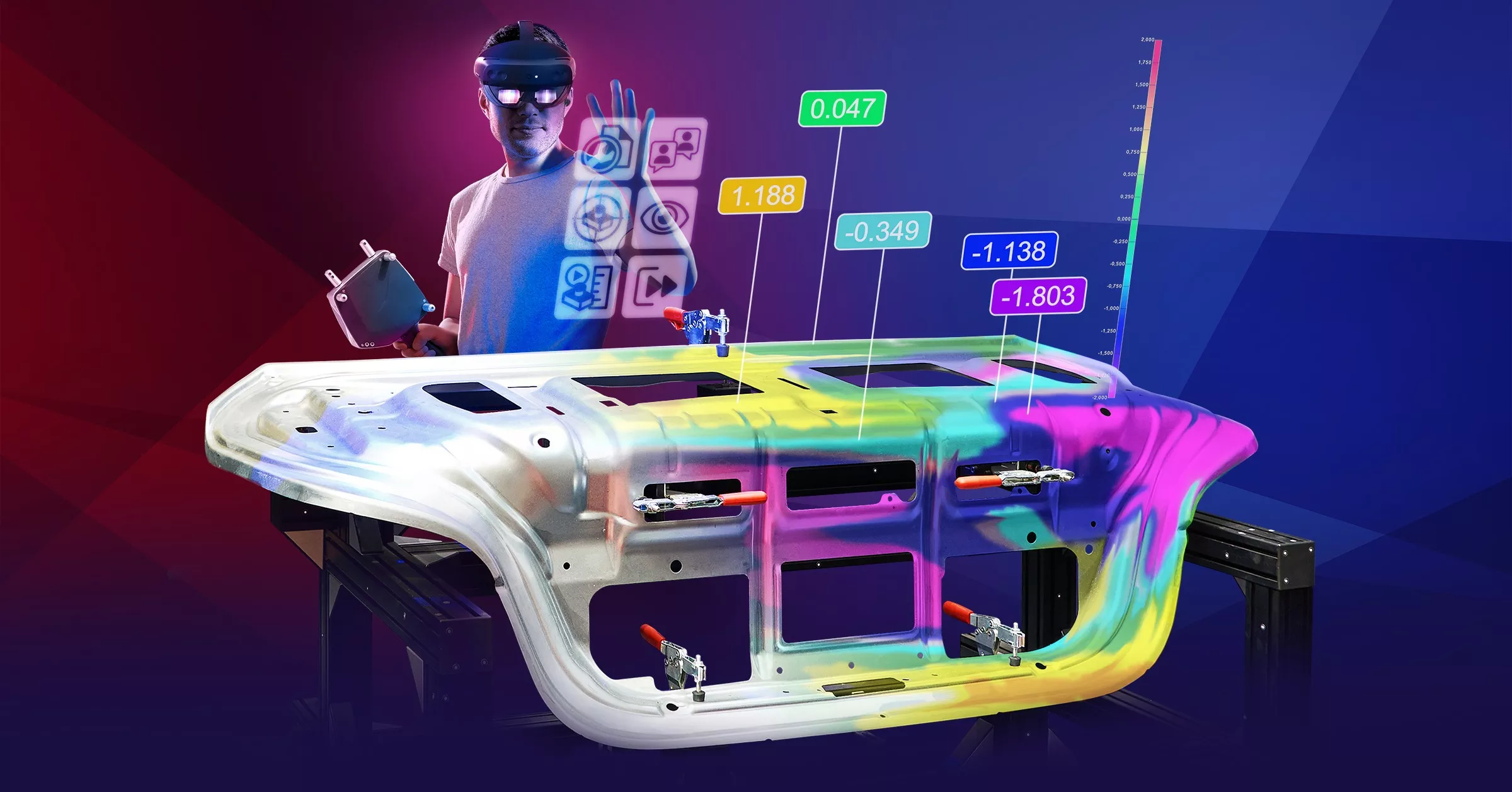

Boost your large-scale 3D measurement performance with mixed reality display technology

Mixed reality display technologies are transforming large-scale metrology tasks by providing localized visual guidance, measurement feedback, and access to inspection functionalities, without encumbering the hands of operators. The PolyWorks® 2023 mixed reality app offers new powerful tools to guide laser scanning, review inspection results, and collaborate with colleagues:

Position the hologram of the PolyWorks|Inspector™ 3D Scene window within your field of view:

- See your scanning progression as a polygonal surface

- Perform additional scanning in areas of poor data quality

- Know exactly where to scan features and when enough data has been acquired for good feature extraction

Review feature deviations and color maps directly over the measured piece following each measurement task.

Collaborate with colleagues anywhere:

- Call them through Microsoft Teams

- Review inspection results collaboratively by projecting holograms on the measured piece

- Discuss manufacturing issues efficiently by showing them defective areas

Simplify the project preparation and 3D measurement processes

Set up measurement templates and perform 3D measurement tasks more efficiently:

Analyze and edit large measurement sequences more quickly by finding steps using keyword searches or navigating through step types, such as errors and warnings.

Replace the source objects of a dependent feature and preserve all related objects, data alignments, and reports created from the feature.

Create curve-based features in a single click over a polygonal model of a measured piece to more rapidly inspect a piece without CAD data.

Add flexibility to your GD&T toolbox

Get the most out of CNC CMM measurements obtained by tactile scanning

Reduce the noise resulting from the from the manufacturing and measurement processes by filtering tactile-scanned feature curves.

Become a beta tester of our new intuitive ribbon menu!

Help us enhance the efficiency of your workflows

In addition to celebrating the 30th anniversary of InnovMetric, 2024 will also be the debut year of the new PolyWorks ribbon menu. We are transforming your user experience so you can:

- Learn PolyWorks more quickly

- Remember your workflow and retrieve your favorite tools easily

- Discover our powerful functionalities intuitively

With your help, we can make PolyWorks better. Stay tuned for our beta testing program announcement!

Get help

buying

Connect with a specialist who will answer

your pricing and licensing questions.